How Automation in Manufacturing Drives Efficiency for Your Project

At Tool Technology, we’ve invested heavily in automation in manufacturing, from our digital tech stack to our advanced machining equipment. As the industry continues to rapidly evolve, our commitment has always been to stay at the forefront. That way, we can deliver the highest quality results as efficiently as possible.

That commitment influences nearly every stage of our manufacturing process. To show you the difference automation makes to your project, let’s walk through the path a part takes in our shop and all the ways in which it may be assisted by automation and state-of-the-art tech.

A Faster, Smarter Quoting Stage

We’ve refined our process over the years to ensure we respond with quick quotes as often as possible, leveraging Paperless Parts, a digital quoting platform to automate many of the important steps. Customers often tell us we’re the first to respond, a notable benefit in helping to keep your project moving.

Artificial intelligence within this platform automatically flags potential design-for-manufacturing (DFM) concerns, allowing us to recommend small design changes that could reduce costs and lead to faster production.

Just as importantly, our system immediately identifies jobs with requirements our shop can’t deliver, so that customers won’t have to wait days for a no-quote. This transparency is important to us because we never want buyers to waste valuable time at this stage.

Preparation and Scheduling After the PO

Once a purchase order is received, preparation begins immediately. We never want a situation where we reach our start date and we have our material only to find that a tool was missing or wasn’t right for the project.

With our ProShop ERP, we can generate a complete production schedule within minutes. Even when we’re managing outside processes for a customer like heat treating or anodizing, ProShop accounts for these in all deadlines to keep production steady.

At the same time, High QA software quickly balloons, prints, and organizes inspection plans, whether the customer needs critical features only or 100% inspection. By handling quality plans upfront, we never risk delays late in the process.

Engineering and Proving Out

Even before material arrives, our team reviews parts for potential challenges and problems that may require new purchases like specialized tooling. Once the stock is in our shop, we’re already well ahead of the game, and we’re ready to prove out the most efficient way to run the job. All of these proactive steps minimize spindle downtime for any project in our shop, and by saving and reusing programs, we can automate repeat production long-term.

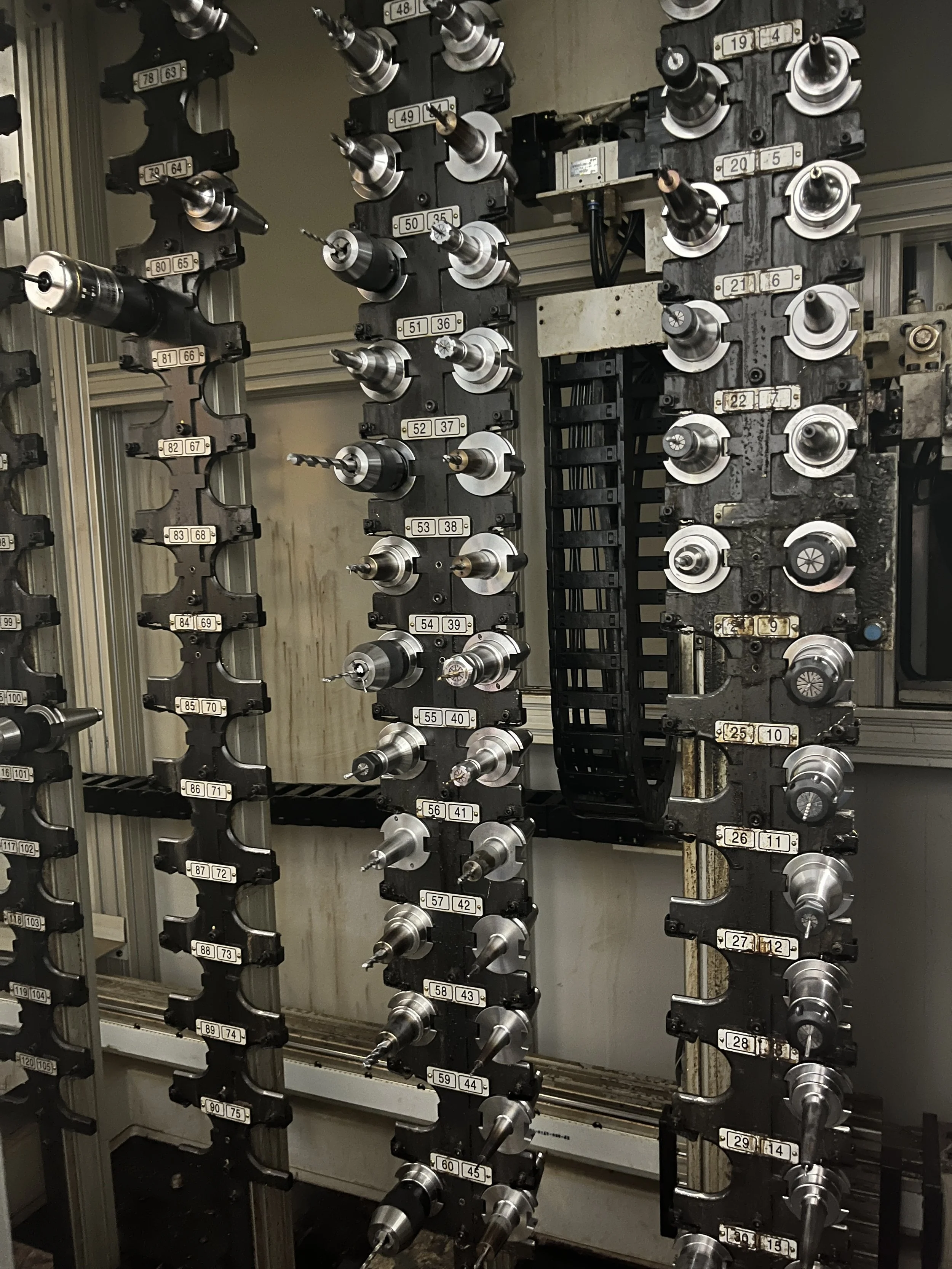

Running in the Automated Cell

With four horizontal machines integrated with robotics for automated part handling, our automated cell is a perfect example of the effectiveness of automation in precision machining. Each machine includes 330 tooling stations, so tooling can be prepared well in advance while other jobs are run.

The robot selects pallets and keeps the machines operating continuously, even lights-out. Its flexibility lets us switch between long production runs and high-mix low-volume machining, with minimal intervention from our team.

Why Repeat Production Is Even Simpler

With programming complete, tooling already set up in our robotic cell, and detailed process notes, we can get started almost instantly on repeat production runs.

Currently, for instance, two of the machines in our cell are producing thousands of precision machined components from stainless steel for one customer, with hundreds shipped out daily. At the same time, another machine in the cell is handling repeat short-run work for a high-tech client. This versatility allows us to serve a wide range of industries and customer needs.

Automated Inspection for Reliable Quality

Our reliable quality is supported by automation, as well. Our coordinate measuring machines (CMMs) can be programmed for automated inspection. Once set up, the process requires minimal operator involvement and can easily be run again in the future for repeat parts. That means our inspectors can manage other tasks in the shop without ever compromising on accuracy.

What It Means for You

Everywhere we can, we use automation to enhance our work. When you partner with Tool Tech, you gain a team that embraces innovation in every possible way to benefit your business. If you need CNC milling and turning, we’re ready to tackle your next project.

Request a quote and see how simple your next project can be with our Massachusetts machine shop!