The Philosophy Behind Our Precision Parts: Focus on Customer Value

With a new year arriving, we’ve been thinking about manufacturing strategy and the future here at Tool Technology. We’ve been in business for more than 50 years, but we never stop looking for ways to improve how we manufacture precision parts.

In recent years, that’s led to several major investments. These additions have touched many areas of our business, but all of them follow one core philosophy: stay at the forefront of technology so we can deliver the best experience for the people who trust us with their parts.

Customer Value: Our North Star

Every successful business needs a clear goal to work toward. For us, that guiding principle is maximizing the value we provide to our customers.

That value is partially measured by classic metrics like on-time delivery and quality ratings, but it also shows up in our efforts to create a simpler customer experience. When we invest in our shop, we want to not only reduce lead times for your precision parts; we want to eliminate friction for you, as well.

The Impact of Our Investments

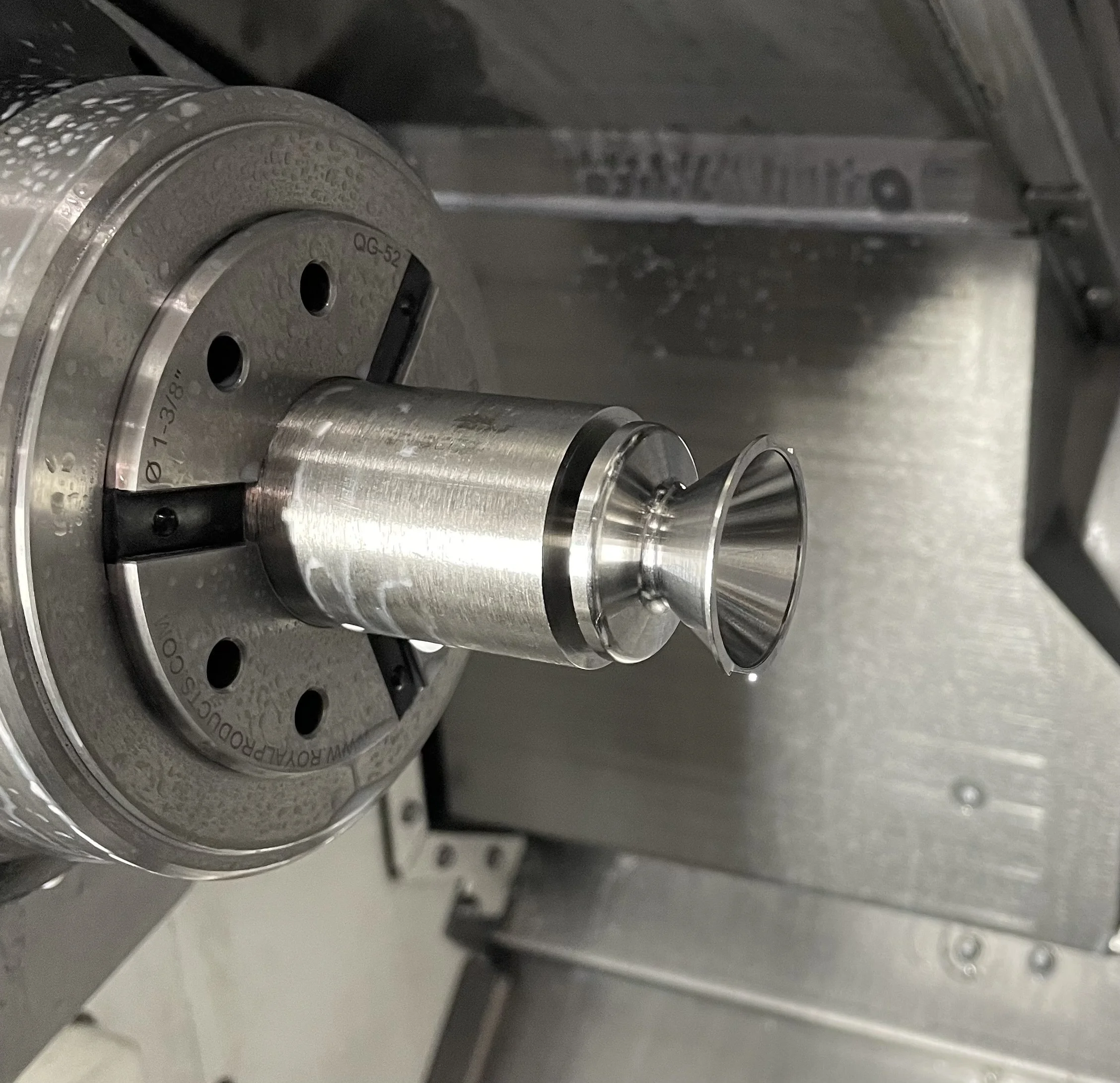

Our recent investments in technology have come in both modern software and machining equipment. All of these tools are intended to improve your experience in multiple ways.

Automated Machining Cell

Our cell, featuring four horizontal machining centers integrated with robotics for part handling, has added capacity to our CNC machining services, but it did more than that. The system gives us flexibility to run multiple jobs at once, handling both high-volume and high-mix work. That makes it easier to support different types of customer projects, from varying complexity to different quantities, without sacrificing delivery.

Modern ERP

Our ProShop ERP has transformed our scheduling and planning while adding transparency to our customer communications. Before a job hits the floor, we can confirm we have the correct material, tools, and documentation, and then we fully kit the job so everything is ready when it reaches the machine. That improves efficiency for your project and helps us communicate our status more clearly.

Quoting Software

Our software helps us respond to RFQs with quick quotes, and it offers several other customer experience benefits as well. It produces clear quotes, streamlines communication, and enables an easy online portal to submit your RFQs.

Planning Our Next Investments

We’re actively evaluating what comes next, and we’re guided by the same customer-focused mindset. Adding 5-axis machining, for instance, is one likely direction. It would allow us to take on more complex projects while adding capacity to our floor. We’re also watching new AI-driven programming tools, which could shorten programming time and further improve consistency from job to job.

Whatever we choose, we won’t just be tempted by fancy new technology for its own sake. We search out the tools and equipment that support better experiences for the customers who rely on us.

Ready to Help

If you’re looking for a Massachusetts machine shop that pairs long-term experience with a commitment to value, let’s discuss your next project. Whether you need complex precision parts or high-volume production, we’re ready with our CNC milling and turning services.