Growing Our Capacity to Deliver Precision, High-Volume Machining

At Tool Technology, we’ve been delivering quality results for more than 50 years, but we’re still always pushing to improve. That’s why, over the past several years, we’ve invested in expanding our capacity to handle more high-volume machining and repeat projects without compromising the precision our customers expect.

When you need accuracy at scale, our Massachusetts machine shop is a perfect match. Learn about the equipment, processes, and technologies driving our continued growth.

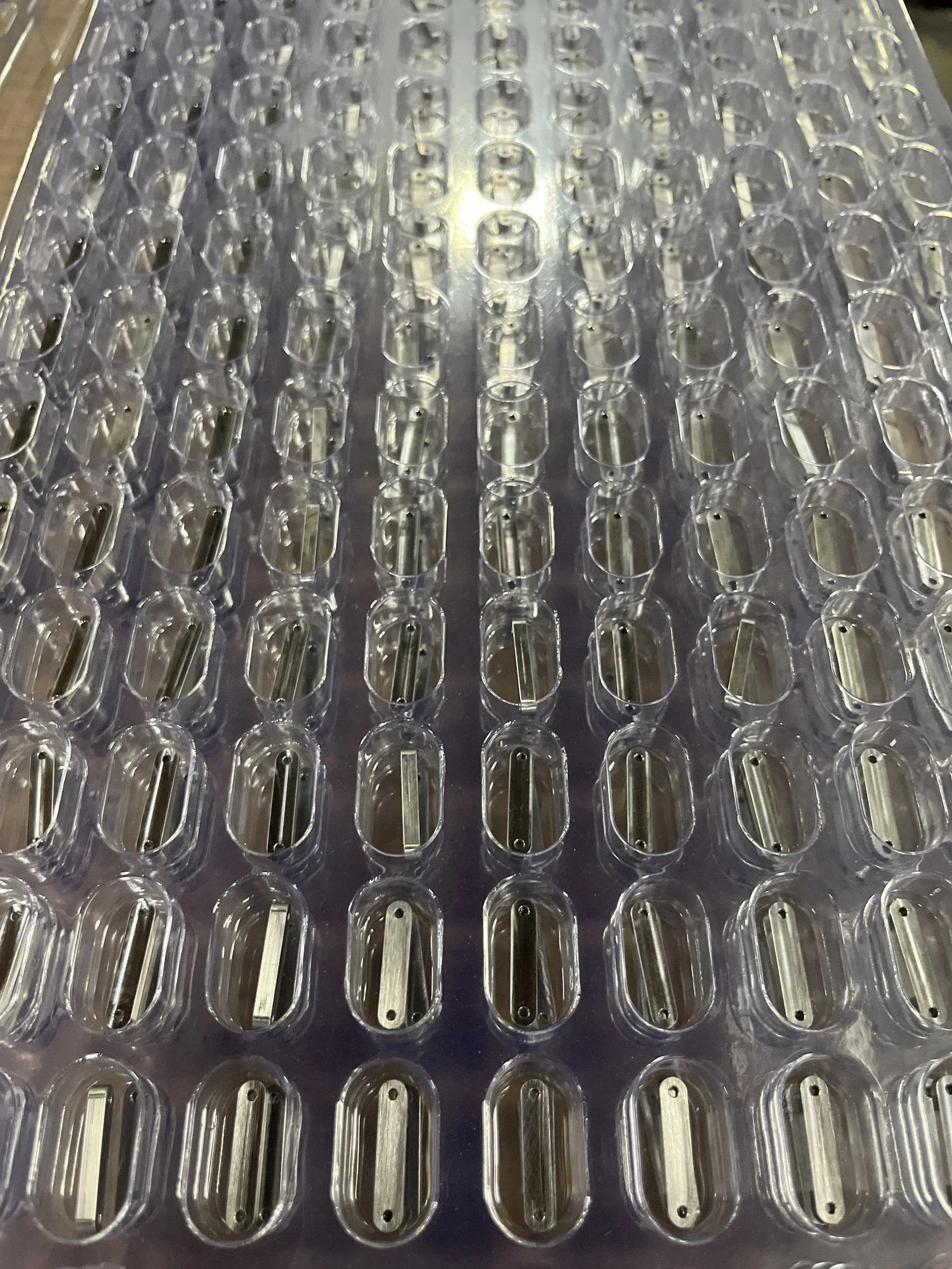

Embracing the Power of Automation and Robotics for High Volumes

One of the biggest drivers of our expanded capacity is our automated machining cell, featuring four horizontal machines integrated with robotics for part handling. Each machine can accommodate up to 300 tools, giving us the capacity to set up multiple jobs at once while handling a wide range of production volumes for our customers.

Once a job is proven out, it can be run with minimal intervention, in many cases even lights-out. This means better timelines and more consistent quality, even at production volumes, with the agility to switch jobs quickly and seamlessly.

Mill-Turn for Efficient Simultaneous Machining

Our advanced mill-turn machine has made our shop extremely efficient with complex, multi-feature parts. We can complete entire parts in a single setup, reducing production time and eliminating the risk of errors that arise when operators have to switch machines.

The multi-turret design of our mill-turn machine also allows for simultaneous machining, which significantly reduces cycle times. Parts that once required three minutes per side can now be completed in just three minutes total. This efficiency gain translates directly into growing capacity and increased availability for high-volume machining.

Beyond Machining: Optimized Scheduling and Fast Inspection

Our transformation extends beyond machining. We’ve analyzed every aspect of our operations to maximize our capacity, and some of our most notable tools include:

Digital ERP

We’ve transformed our operations by moving to a new digital ERP system, eliminating paper travelers and gaining real-time visibility into our production.

Operators can now update job statuses through our ProShop system, giving us insight into where every job stands and how our schedule looks. We’re able to think more strategically about production planning, preparing several jobs in advance to pre-order tooling and stage tooling and materials to reduce downtime.

Precision Inspection

Tool Tech has built its reputation on quality, and our automated coordinate measuring machine (CMM) capabilities have only improved our inspection processes.

We can inspect parts during production, focusing on critical features while at the machines before completing full-part checks later. In addition, our custom fixtures allow us to inspect multiple parts or surfaces at the same time.

Let’s Discuss Your Next Project

Even as our shop has evolved, we’re still looking to the future. Over the coming years, we plan to continue investing in our high-volume machining capacity while remaining as committed to quality as ever. Whether you need CNC milling and turning or an ITAR-registered manufacturer, we’re ready.

Request a quote today to partner with our precision machine shop on your next project!