Manufacturing Quality: How We Maintain a 98%+ Rating

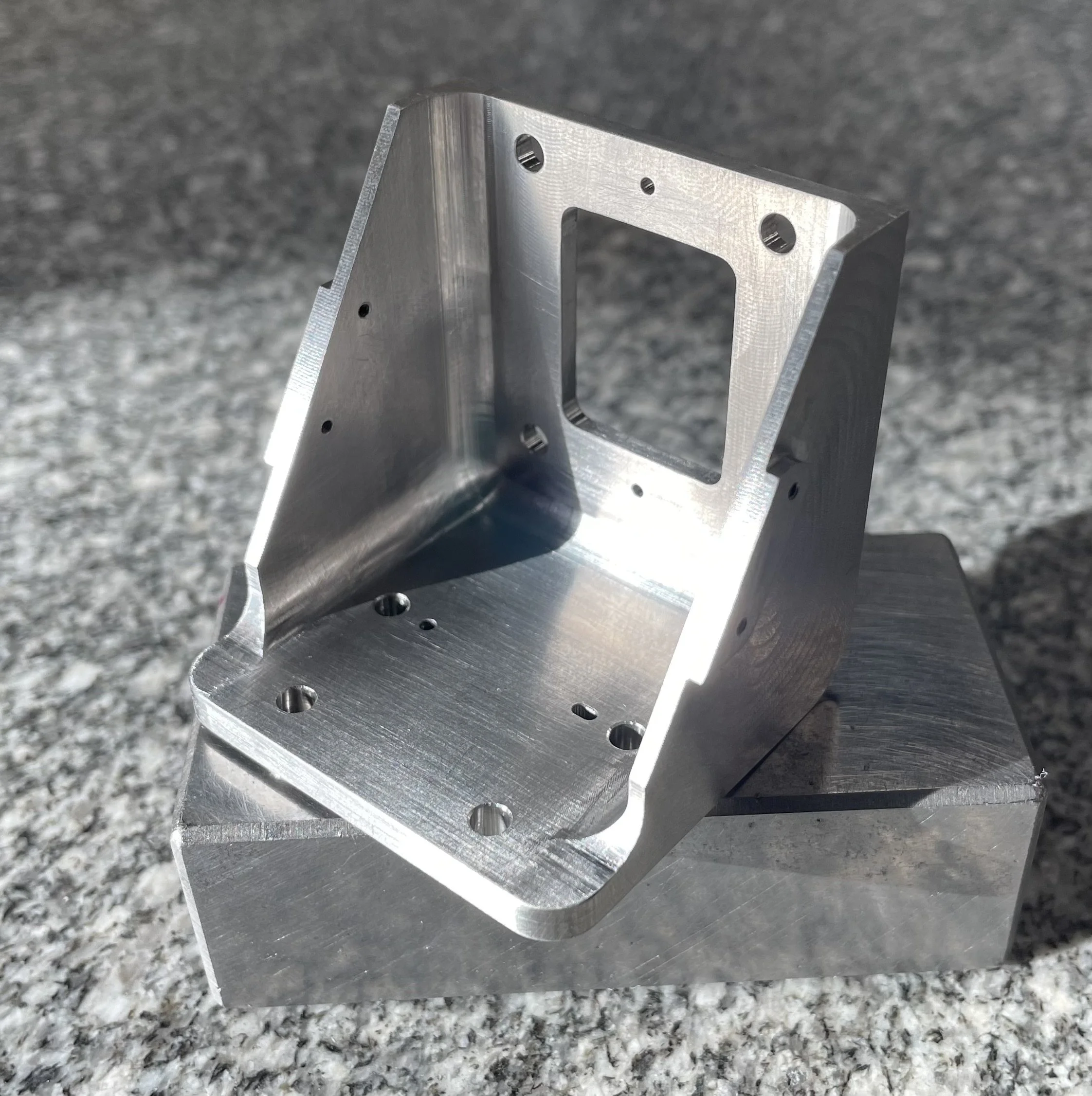

At Tool Technology, we’ve long had a reputation for delivering the highest manufacturing quality. From the start, we’ve served demanding industries like aerospace, where there’s no margin for error. That experience has shaped our mindset, and our commitment to excellence has only grown over our decades in business.

By combining cutting-edge equipment, software, and processes in our shop, we’ve continued improving our quality in recent years. Learn how we achieve the highest quality, and find out the numbers that prove it.

Our Quality Rating: Over 98%

Plenty of shops claim to be “quality-focused,” but we can back that claim with hard data. As an ISO 9001-certified and ISO 13485-certified shop, we measure and review our quality performance regularly. Twice a year during our ISO management reviews, we discuss metrics in detail.

In our most recent review, our external quality rating was over 98%. We’re proud of this achievement, and we think it speaks to our consistency in the industries we serve.

Our owners, Gregg and Brian Noel, have built a culture on quality, and they’re personally committed to upholding our standards. If a rare quality issue arises, they take accountability and respond to the issue themselves. That leadership sets the tone throughout our Massachusetts machine shop that quality is not negotiable.

The Certifications That Matter

We’ve invested the resources to obtain certifications that give our customers confidence in our quality, our processes, and our capabilities. These include:

ISO 9001: Quality management systems for reliable production and documented processes.

ISO 13485: Quality management standards specific to medical device manufacturing.

AS9100: Aerospace industry quality standards ensuring traceability, risk management, and process control.

ITAR-Registered Manufacturer: We securely handle defense-related projects and safeguard sensitive information.

We can meet required quality modules for FAIs and certifications, and we align with customers from the start on specific manufacturing quality requirements for their projects.

Dedicated to Quality at Every Step

Our quality department uses advanced tools such as our Hexagon Global S CMM to ensure precision, but it’s important to realize our inspector doesn’t just check parts at the end of production. He’s involved early in the process, helping our machinists proactively plan to prevent defects before they happen.

Machines in our quality department are calibrated annually, and strict inspection protocols are in place. We use High QA software to balloon prints and create quality plans in minutes. This used to be a time-consuming manual process, but High QA has significantly reduced the time involved, helping to speed up production.

Partner With Us for Long-Term Quality

With Tool Tech, you’ll be collaborating with a partner that’s committed to manufacturing quality in every sense of the word. We’ve built it into our culture and our processes, supporting it with technology and certifications. Our documentation ensures repeatability, and our automation and process control allow the job to run consistently every single time.

Whether you need an expert aerospace manufacturer or you’re looking for repeat production in any other demanding industry, we’re ready to partner with you. You can count on us to deliver the results that meet your requirements the first time.

Request a quote today to see how our deep focus on quality can lead to a better manufacturing experience on your next project!